Scientific Efficiency Analysis

by Dr.-Ing. Olaf Przybilski

What kind of concrete technical solutions did Walter Thiel provide for the demands of chemical and thermo-dynamic processes in the development of thrust chambers for rocket engines? The following deliberations are an extract of an extensive scientific work by the author that will be published soon. In the following, the most important steps are shown how the groundbreaking thrust chamber head was fundamentally changed under the guidance of Walter Thiel (sources are listed in the yet to be published documentation).

The author’s conclusion can be summed up like

this: Kummersdorf is not the “craddle of space flight”, but the birthplace of

modern-day liquid-propellant engines that were significantly influenced by Dr. Walter

Thiel!

Dezember 5, 1935: The company Ernst Heinkel

Flugzeugwerke GmbH announces to the Heereswaffenamt (HWa), namely “Dr. von

Braun“, “that we have reached a stage in our first project where it is now

necessary to have the smoke oven for 1000 kg (roughly 10 kN of thrust)”.

July 22, 1936: In technical drawings the

author could identify for the first time that a “congestion“ of the gas flow in

front of the narrowest cross-section could be avoided. This is probably one of

the first improvements that the latest member of the team, chemist Dr. Walter

Thiel, added to the project. The angle is now 60° generally.

September 26, 1936: Since taking over the

development of the rocket engines, Walter Thiel’s R & D department was working

on a number of rockets with the same or similar exterior and interior design as

the Aggregat 3 (e.g. to minimize size and optimize positioning the thrust

chamber is always integrated into the fuel tank), and the thrust of the thrust

chambers was 5, 10, 60 or 100t respectively.

Until the end of 1936 there was no major breakthrough in mass reduction in so far developed thrust chambers made of aluminum, which was considered a decisive precondition for the use in airplanes. Mainly cooling problems of the thrust chamber wall posed an unsurmountable obstacle for the scientists in those days.

February 12, 1937:

Decisive talks between HWa and RLM mark the start of cooperations between HWa

and the industry as well as research institutions, among others the company

Gustav Schlick from Dresden. This was probably one of the first official acts

of Walter Thiel as the new specialist for research and development issues.

July 1937: From the results of chemical tests at the

Charlottenburg University of Berlin in 1932 Thiel develops a new, adjustable

thrust chamber head for JATO engines, which is now conical.

August 1937: Walter Thiel’s findings in „Empirische und theoretische Grundlagen zur Neuberechnung von Öfen und Versuchsdaten“ (GD 634.190.8, FE 573, Deutsches Museum München, German Documents Archive) summarize the until then known rules and principles.

Subsequently, Thiel purports for the first time

the corelation between thrust chamber volume (cm³) and the nozzle throat area (cm²): today it is named L* (speak: L star).

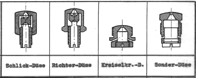

September 1937: Based on the before mentioned constructive solution from August, the hugely tested centrifugal injector ("Kreiselkraft"-injector) of the company Gustav Schlick will lead to a breakthrough (positioned “in the right place“ INSIDE the wall).

October 1, 1937: A research report on ongoing developments shows that different injection systems were tested in different-sized kilns.

Beginning of 1938: After recognizing the advantages of drilled injectors, a ball- or cone-shaped head is fitted with rows of fuel-injection nozzles made of brass, which are adjusted to the thinner walls.

April 3, 1938: Both construction types appear in a patent specification with the title “Rakete“ (Rocket) (GD 624.194.3, FE 200, Deutsches Museum München, German Documents Archive). According to the cover letter the patent applicants are Dr. Walter Dornberger in Berlin-Charlottenburg and Dr. Walter Thiel in Kummersdorf (without any reference to a military facility).

Mid July 1938: Thiel decides that the

developed injection system from the preliminary illustration V 246 C from the 1

t-chamber should be transferred to its smaller “sister“. The 725 kg chamber is

redeveloped (type 5B) for the sole rocket engine of the He 112 V4.

August 26, 1938: Systematic tests of Thiel’s

research team on the testing range P 5 at Kummersdorf with a thrust chamber

delivering 100 kg of thrust. The major result was an angle of 30o for the nozzle. This would lead to a significant reduction in

material, weight and work processes, as well as a shortening in the length of

the engine itself. The 25 t-thrust chambers in Peenemünde, built according to the plans in

Kummersdorf, would only have a length of 1.6m, compared to 4.2m of the 1936

model with 20 t chambers.

September 1938: The technical drawings

reveal that nearly all thrust chambers with an internal pressure of 11 bar had

„Kreiselkraft“-injector. Even the subsequently developed thrust chambers with

higher internal pressure (26 bar) contained these injectors, and these were usually

only fitted in Kummersdorf.

End of 1938: By the end of 1938 it was

common knowledge that the atomisation of the liquid oxygen (also called LOX)

was not the primary problem. The liquid easily evaporated in the chamber due to

the existing differences in temperature. An oxygen vaporizer developed for

aircraft thrust chambers was implemented additionally in the 25 t-chamber

development as of 1939.

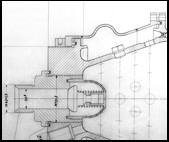

January 19, 1939: First technical drawings of a large thrust chamber with the name 6B/10 appear on the drawing board in Kummersdorf (type 6B with 10 atü [air pressure over ambient] = 11 bar internal pressure).

Beginning of 1939: The philosophy regarding the setup of an optimized vaporisation system meant clearcut testing with different results. For the optimized positioning of the rocket it is very beneficial to place the thrust chambers next to each other instead of in a line. Different setups of the vaporisation system were tested.

End of April 1939: The very first fire tests with large amounts of thrust thrust fail in Peenemünde on testing range PI. Due to cooling problems in the 19-pot head, especially in the middle section, both 25-tonners explode.

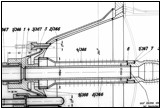

May 26/27, 1939: First successful fire test of a 25-t engine at the Peenemünde P I testing range (roughly 90 seconds). It was an 8-star oven called 6B7K/10 atü (see drawing).

October 2, 1939: Thiel sends reports on practical tests on small thrust chambers from Kummersdorf. The use of ethanol as a "film cooling jacket" inside the chamber will facilitate the construction of the 25-t engine, e.g. the thick walls of the aluminum alloy are no longer necessary.

November 29, 1939: An 18-pot oven is designed on the drawing boards of Kummersdorf (type 6B10P/13 atü – see the drawing) The centrally positioned main valve reduced the number of vaporisation systems to 18, in addition this model has a 3-layer head design that provides two headrooms, where the ethanol first cools the head and then flows towards the valve and to the room above to cool the different “pots”.

The shortly afterwards implemented drills for film cooling finally stabilize the engine thermally.

March 21, 1940: Start of combustion tests on the 18-pot 13 atü oven on the Peenemünde P I testing range. The very first tests generate high outflow speeds of 1700 m/s.

December 17, 1940: After only 48 tests with 7

different thrust chambers the advance development is completed. The outflow speed

is now 1950 m/s. After that the vaporisation system was further optimized.

September 15, 1941: The final report of the 25.4

t 18-pot oven is released by Thiel. The outflow velocity is 2600 m/s at 16 bar

internal pressure. The oven’s head, made of aluminum alloy, is screwed onto the

steel jet for the time being.

June 19, 1942: The thrust chamber made

entirely of steel is ready for serial production (series B). The currently

developed vaporising system will not be altered until the end of the war, and

it will later even serve as a prototype for the thrust chamber RD-100 of the

R-1 of the Soviet Union.

August 18, 1943: Walter Thiel is killed

during an allied bombing raid on the north of Usedom, but this has no influence

whatsoever on the development of the thrust chamber of Aggregat 4.